YIZUMI Makes a Splash at INTERPLAST 2024 with Powerful Machines

Abstract:

Aug. 13th - 16th, 2024 Expoville Pavillions, Joinville, Brazil Booth 502

On Aug. 13th, the highly anticipated INTERPLAST 2024 raises the curtain at the Expoville Pavillions in Joinville, Brazil. The four-day event brings together top global companies in the plastics and rubber industries to display the latest technological achievements and industry trends.

During the event, YIZUMI Brazil and its famous local agent Alltech present several flagship machines and turnkey solutions at booth 502. These innovations show YIZUMI's strong strength in the industry while also attract the attention of global visitors.

Innovative Molding Solutions

Cup Molding Solution

The P-S3 series high-speed injection molding machine is suitable for molding multi-cavity thin-wall packaging products. It has many advantages, including high rigidity, high injection speed, and high precision. In addition, it has increased the maximum system pressure by over 10% to 19MPa, and overall rigidity of clamping unit by over 25%. These enhancements are beneficial for molding thin-wall, deep-cavity products, enabling it to meet customer automation needs and provide turnkey solutions such as labeling systems.

Demo production of cups by P380S3

Demo Production Details:

Product: Cup

Material: PP CJS700

Size: Φ104x172.3mm

Wall thickness:1.2mm

Number of cavities:2

Weight:56±1g

Cycle time:Around 10s

Collapsible Basket Molding Solution

The UN260C-BTP injection molding machine achieves one-step molding with both "injection molding material + polyurethane", significantly shortening processing cycle, increasing production efficiency and reducing production costs. It is also equipped with turntable mold technology, which allows for rapid and accurate molding, making it ideal for producing thin-wall PUR parts with 3D depth of field and multi-grain surfaces, such as automotive interior parts. It offers high gloss, scratch resistance, and other features. Furthermore, it is environmentally friendly and energy-efficient, with zero-VOC emissions during the manufacturing process, aligning with the green manufacturing trend.

Demo production of collapsible baskets by UN260C-BTP

Demo Production Details:

Product: Collapsible basket

Material:PP+TPE

Number of cavities:1+1

Weight:91+56g

Cycle time:30s

Small Batch Customization Solution

The SpaceA industrial pellet 3D printing has several core benefits, including high efficiency, low cost, flexible customization, and high quality. It uses a screw extrusion system, which greatly increases production efficiency and allows it to respond swiftly to market demand. At the same time, the use of granular raw materials significantly reduces costs when compared to traditional ways, and it is also compatible with a wide range of materials, including modified plastics and special materials, meeting diverse production needs and expanding industrial manufacturing possibilities.

Demo production of wine bottle holders by SpaceA industrial pellet 3D printing

Demo Production Details:

Product: Wine bottle holder

Application: Decoration

Material:AKROLEN ® PP ICF 30 AM

Cycle time: 45 min

Exhibits

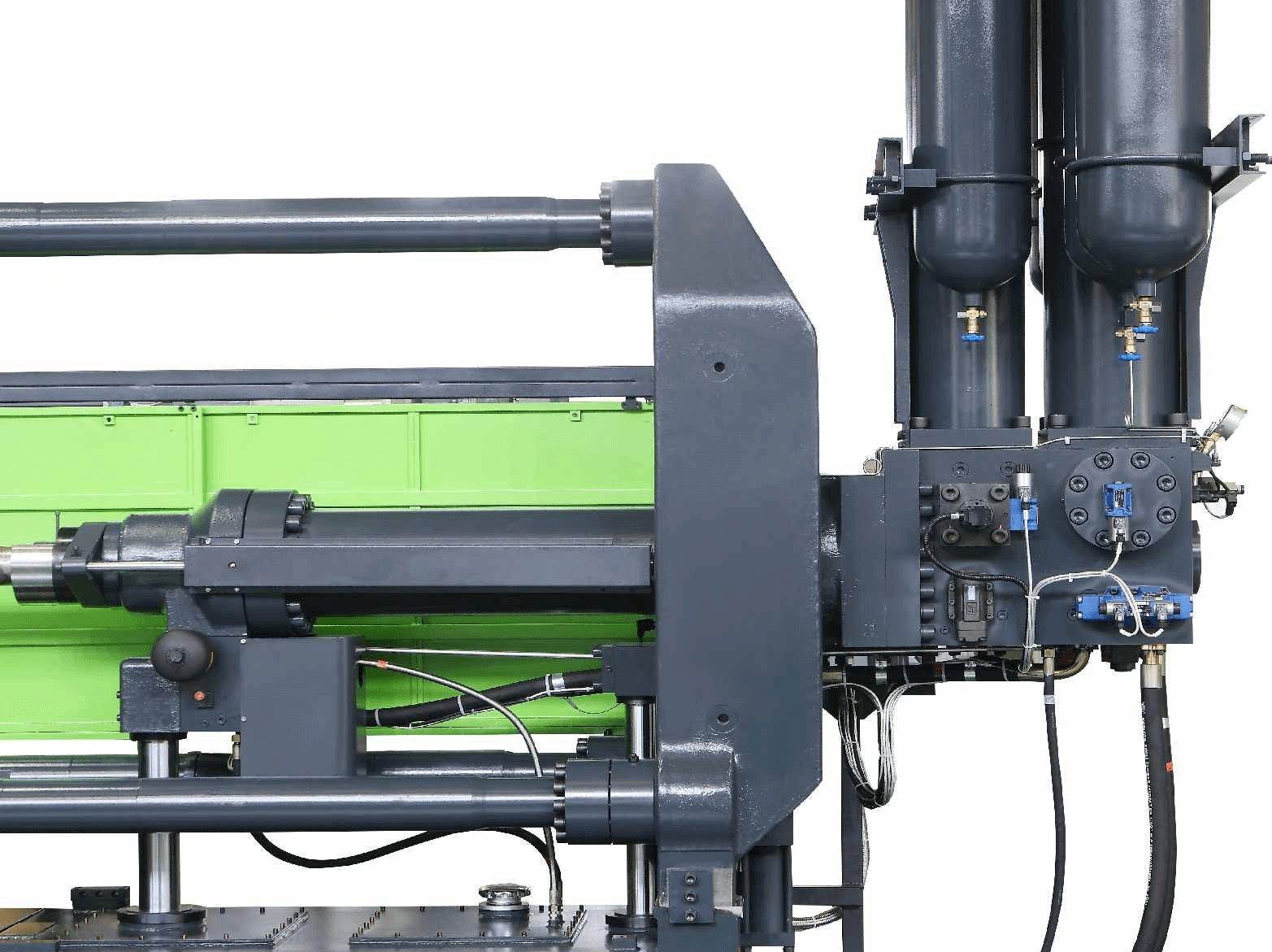

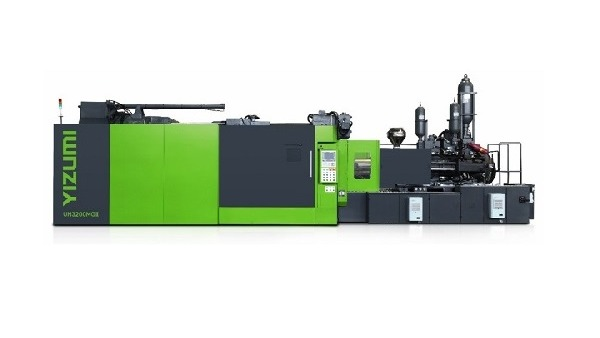

UN260SKⅢ Injection Molding Machine

The UN260SKⅢ precision servo injection molding machine features an upgraded injection unit for increased rigidity. The optimized design of its screw and barrel units reduces various frictional resistances during the injection process, thereby improving injection accuracy and ensuring injection stability.

FF120 Electric Injection Molding Machine

The FF120 electric injection molding machine adopts a modular design that clamping units and various injection units can be combined flexibly as customers' demands, with injection speed ranging from 160 to 500 mm/s. The position accuracy of injection and mold opening & closing is within 0.03 mm, satisfying the demands of global customers for high precision, high efficiency, high stability and automation.

Expanding into Brazil's Growing Market:

Brazil, as Latin America's economic powerhouse, is facing a dual test of volatility and recovery in its plastic industry. In recent years, despite supply chain disruptions and development obstacles in the industry structure, the Brazilian plastics industry has shown strong resilience and recovery momentum.

In terms of market demand, the Brazilian plastic industry is heavily driven by several industries, including packaging, construction, automobiles, and agriculture. The demand for plastic products is increasingly grow, particularly in the packaging and construction industries. Meanwhile, the rapid development of new energy vehicles has increased demand for plastic parts in the automotive industry. The Brazilian plastic market thereby is steadily expanding.

YIZUMI's Strategic Expansion in Brazil:

In this context, YIZUMI is actively expanding into the Brazilian market by not only establishing a subsidiary and service centers, but also positively promoting its products and services through various means such as collaboration with local agents and exhibition participation, thereby increasing its international competitiveness. All of these actions indicate YIZUMI's strategic insights and execution in the global market layout, and provides a solid foundation for its deep cultivation in Brazil and the whole Latin American market.

YIZUMI Joinville Technical Center (Brazil)

Looking Forward:

In the future, YIZUMI will adhere to the principle of "Sustainable, innovative technology for humankind", constantly exploring and adapting to local market needs, and providing customers with more customized and efficient molding equipment and solutions. We believe that as the local economy and plastics industry develop, YIZUMI's expansion into Brazil will become even more appealing.