Machine Introduction Video

Machine Introduction Video

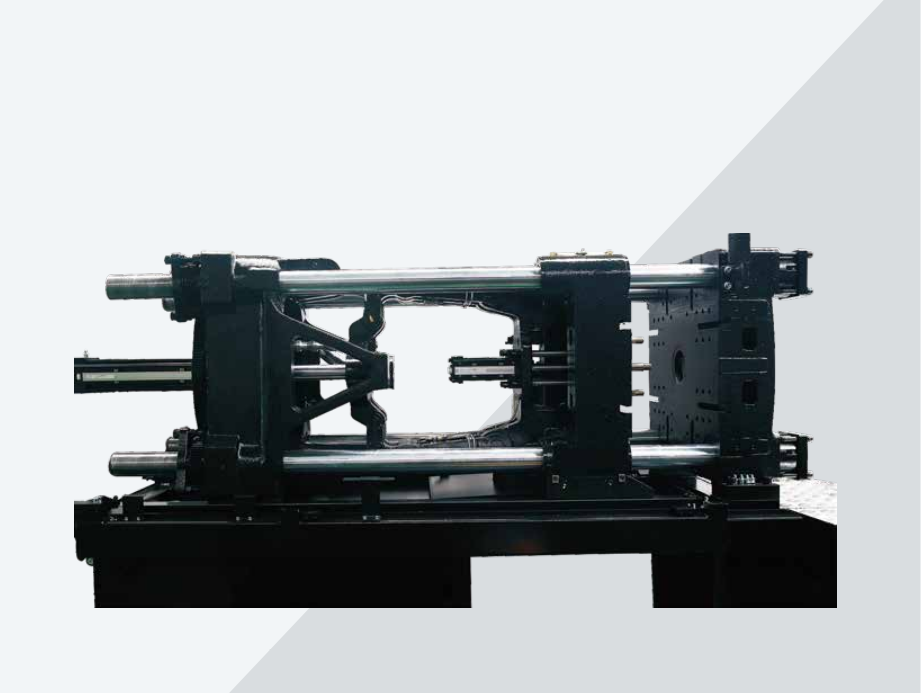

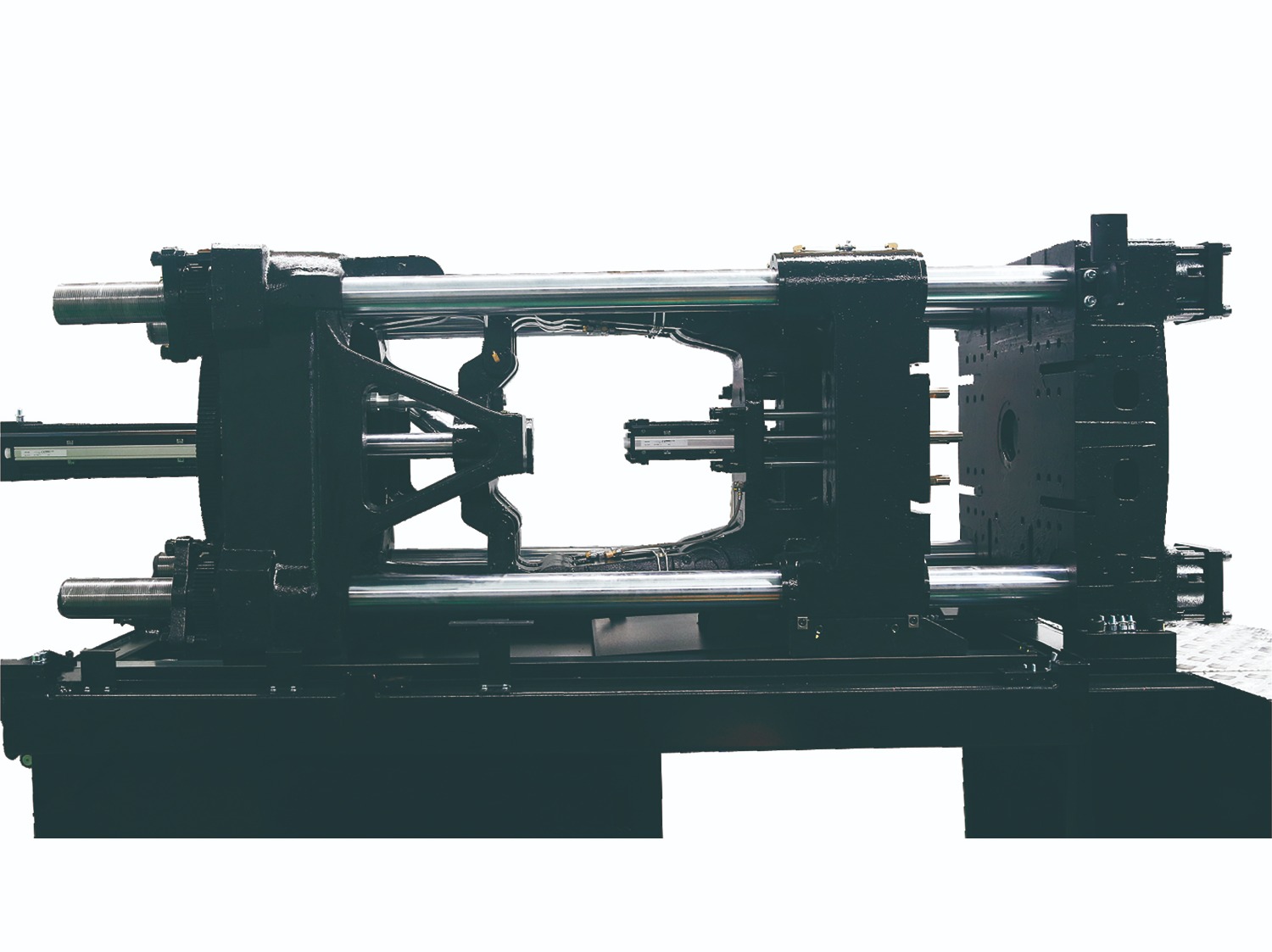

Clamping Unit

High-rigidity T-slot platen

Increases the overall rigidity of clamping unit by

30%, brings convenience for installation and removal

of mold, reduces the wear of thread due to long-term

use of screw hole and extends the life of platen.

Extended moving platen support

- The movable platen is equipped with front heavy-load

sliding supports.

- The center of gravity of support moves forwards to the mold mounting surface, preventing the platen from tilting. Machine still operates steadily when it is loaded with heavy molds.

- The center of gravity of support moves forwards to the mold mounting surface, preventing the platen from tilting. Machine still operates steadily when it is loaded with heavy molds.

Extended ejector guiding platen design

- Ejector guiding extended, effectively avoiding

ejector plate tilting and improving stability of

ejection.

- Uniform distribution of ejector force , precise ejection position with better ejection performance.

- Uniform distribution of ejector force , precise ejection position with better ejection performance.

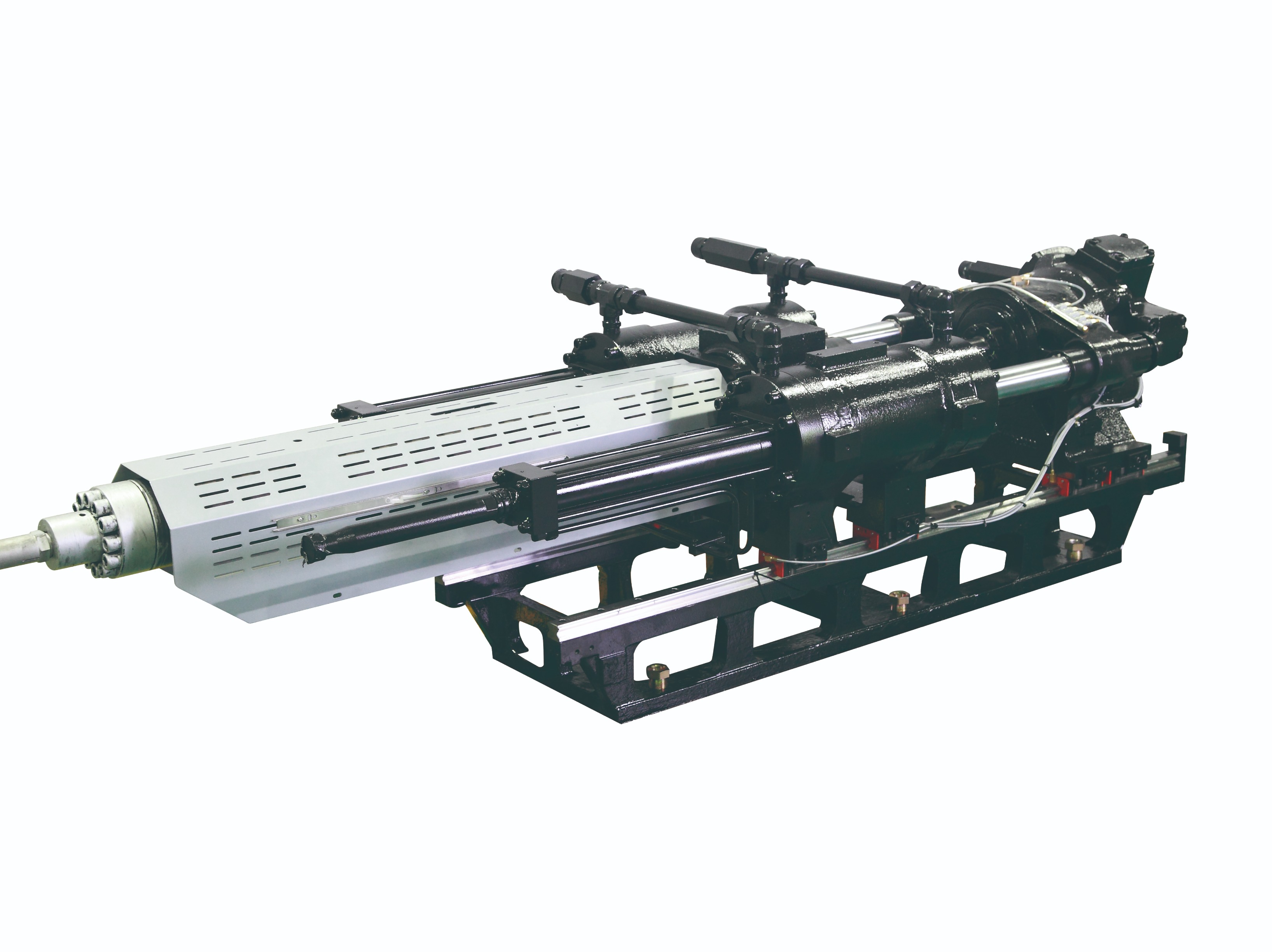

Injection Unit

Integrated linear guide rail structure

- Machine adopts integrated linear guide rail,

horizontal double-carriage design and double-cylinder

injection to ensure injection is reliable &

stable.

- Integrated linear guide rail support reduces the friction between injection unit and linear guide rail or tie bar and enhances production repeatability.

- Integrated linear guide rail support reduces the friction between injection unit and linear guide rail or tie bar and enhances production repeatability.

Three bearings for 290A5-N and larger models

A deep-groove ball bearing is added to the front of

transmission shaft, close to the screw, to improve the

support of transmission shaft, reduce vibration when

it rotates and prolong the service life of thrust

bearing.

Proportional back pressure for plasticizing

Proportional back pressure facilitates accurate

control by industrial computer and enhances the

stability of injection.

Yizumi’s third-generation energy-saving servo technology

- Yizumi has comprehensively grasped the application

technology of energy-saving servo system since it was

further studied in 2005.

- The third-generation servo system has been improved and optimized in the internal structure of motor, the standard of magnetic steel, the selection of oil pump and the development of drive software to achieve superior performance in stability, reliability, durability, energy conservation, efficiency and low noise; the servo system uses 30%-80% less energy than conventional hydraulic machines.

- The third-generation servo system has been improved and optimized in the internal structure of motor, the standard of magnetic steel, the selection of oil pump and the development of drive software to achieve superior performance in stability, reliability, durability, energy conservation, efficiency and low noise; the servo system uses 30%-80% less energy than conventional hydraulic machines.

High precision control system

- A5-N series employs Austria' s KEBA control system

with user-friendly interface and higher processing

speed.

- 12 TFT color touch screen, visualized graphic parameter setting, actual parameter values recorded and displayed with curves, more accurate online process analysis.

- Free programming is available to meet the needs of special molds and processes.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve as needed.

- 12 TFT color touch screen, visualized graphic parameter setting, actual parameter values recorded and displayed with curves, more accurate online process analysis.

- Free programming is available to meet the needs of special molds and processes.

- Extensible I/O modules can integrate with more functions, including temperature control and sequence valve as needed.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data,

collected and processed by YIZUMI in relation to my

inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected

and processed by YIZUMI in relation to my inquiry.