Machine Introduction Video

Machine Introduction Video

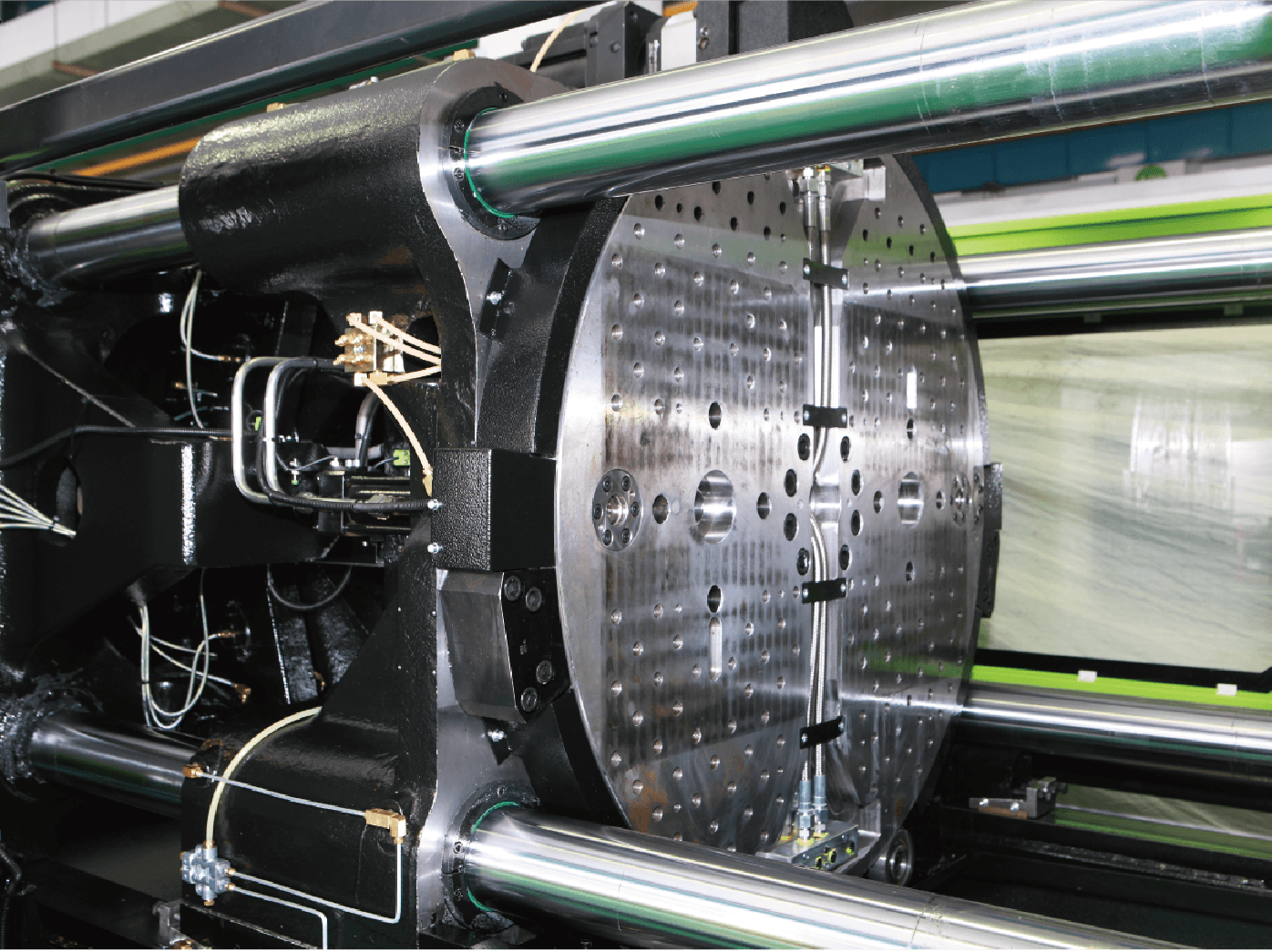

Clamping Unit

Balanced force clamping technology

- The BFC technology delivers high platen rigidity,

long mold life.

- Easily-adjustable processes and minimized possible flashes and better ensures molding accuracy and stability.

- Easily-adjustable processes and minimized possible flashes and better ensures molding accuracy and stability.

Digital closed-loop positioning control technology

The DCPC technology enables the turntable to rotate

smoothly without impact and position accurately.

Magnetically levitated turntable technology

The turntable is designed with magnetic levitation

(for 160T/260T) to reduce frictional loss, increase

the movement reliability and prolong the life of

turntable.

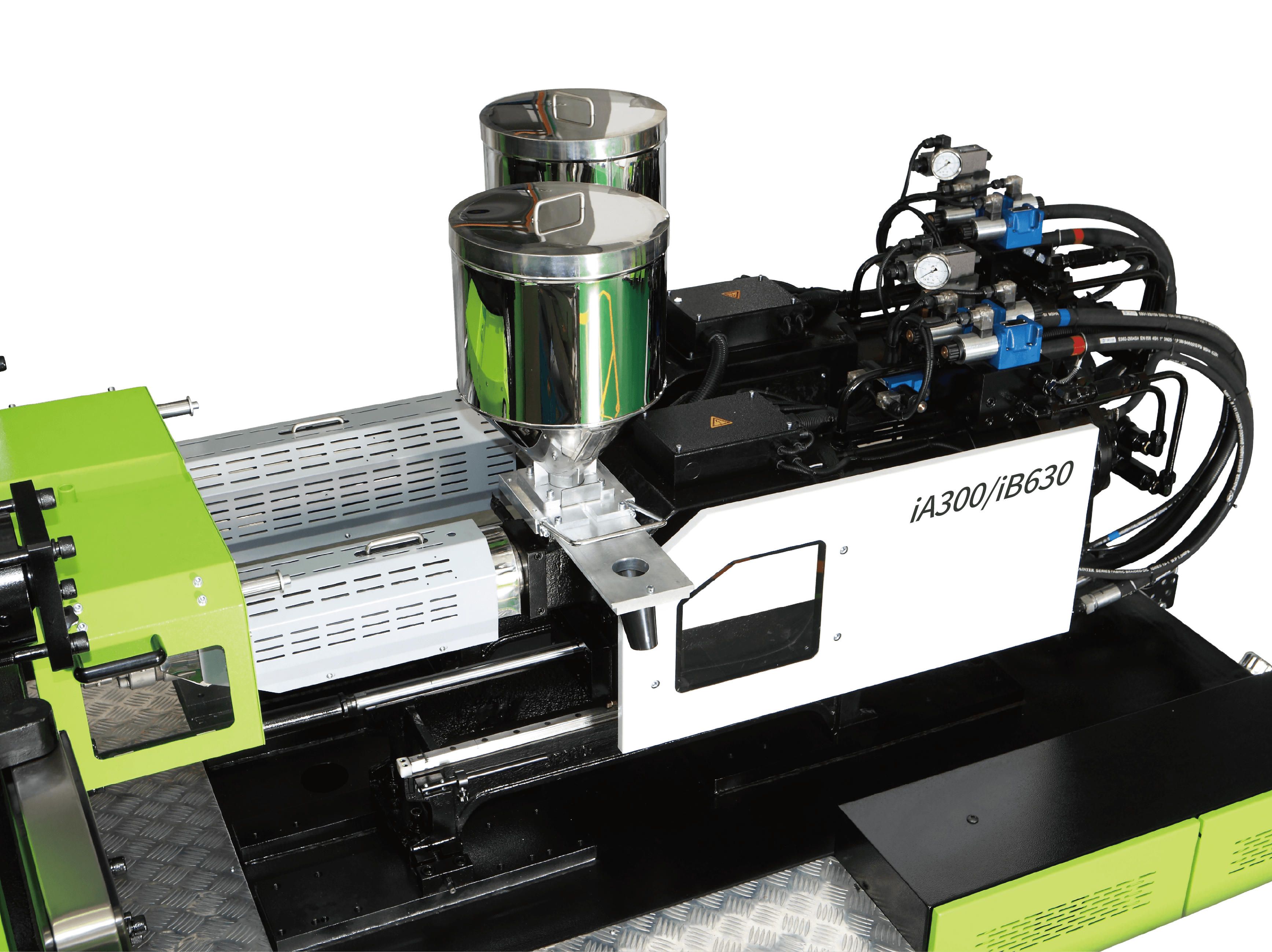

Injection Unit

Modular injection unit combination

Customization is available through the flexible

combination of injection units according to different

processes requirements and flexible software

functions.

High-rigidity low-inertia injection unit

With the adoption of low-inertia moving parts, the

injection movement response is quick and the injection

accuracy is further improved.

New-generation PID temperature control

With the self-adaptive PID temperature control, the

static temperature control accuracy is up to ±0.4

degrees centigrade.

L/V Independent Injection Unit

Independent V injection unit

- Independent V-type injection unit adopts independent

modular design to meet the combination needs of

injection molding machines of different tonnages.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly of molds.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly of molds.

Independent L injection unit

- Independent L-type injection unit adopts independent

modular design to meet the combination needs of

injection molding machines of different tonnages and

different brands. - Flexible injection unit is

convenient for using, providing series functions

including core pulling, sequential valve, hot runner

and synchronous action.

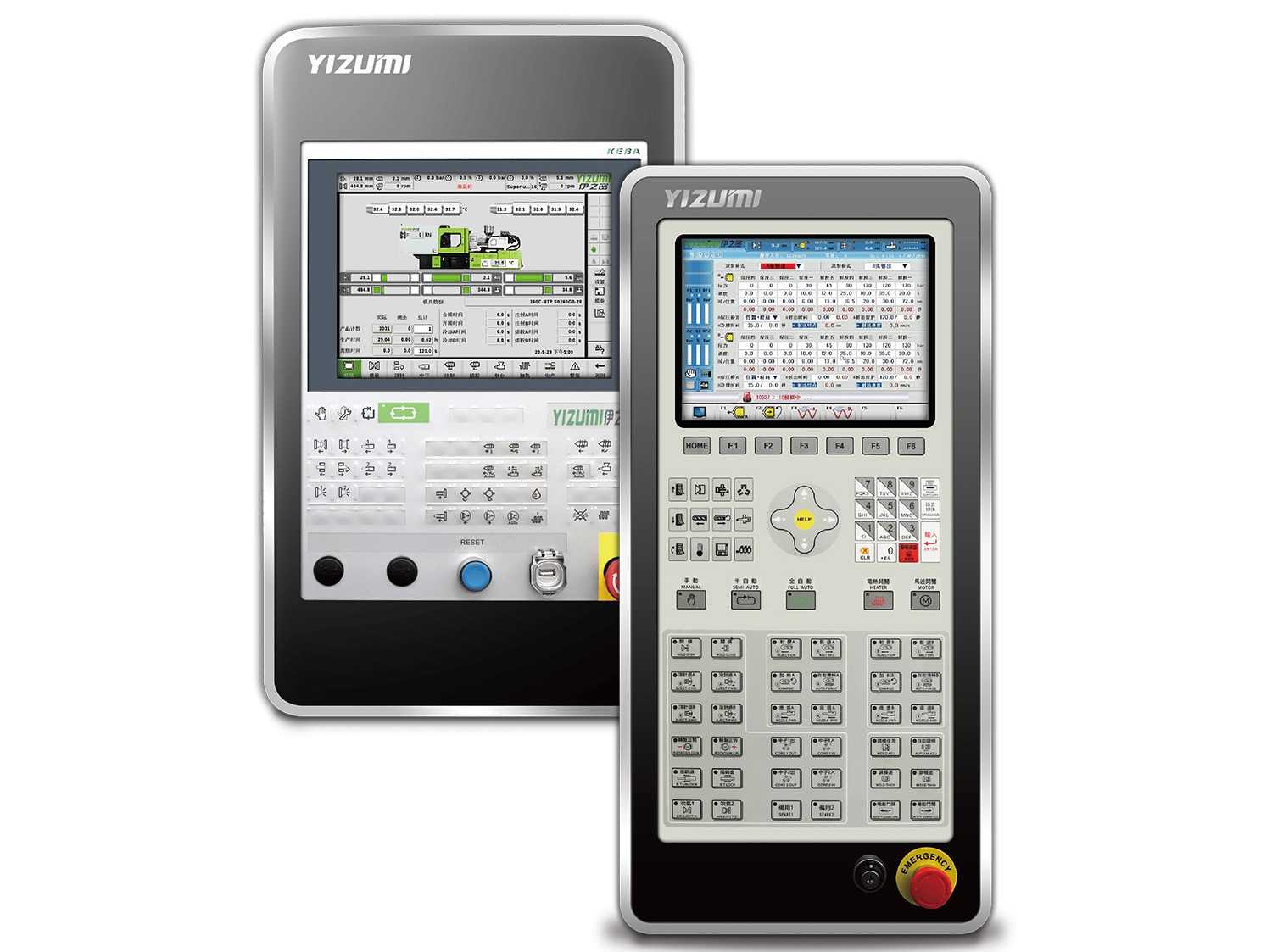

Control System

The powerful and responsive industrial controller for

multi-component injection molding machine can accurately

and synchronously control several injection units, and

exchange data with turntable by synchronous communication

in real time to achieve turntable accurate positioning.

- Remote on-line monitoring of production

- Unlimited parameter storage through USB

- Statistical process control (SPC) for multiple injection units

- Setup and tracking of key movement curves

- Early deceleration and positioning control of movements

- Up to 128-zone built-in hot runner control extension

- Integrated control of auxiliary equipment

- Remote on-line monitoring of production

- Unlimited parameter storage through USB

- Statistical process control (SPC) for multiple injection units

- Setup and tracking of key movement curves

- Early deceleration and positioning control of movements

- Up to 128-zone built-in hot runner control extension

- Integrated control of auxiliary equipment

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data,

collected and processed by YIZUMI in relation to my

inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected

and processed by YIZUMI in relation to my inquiry.