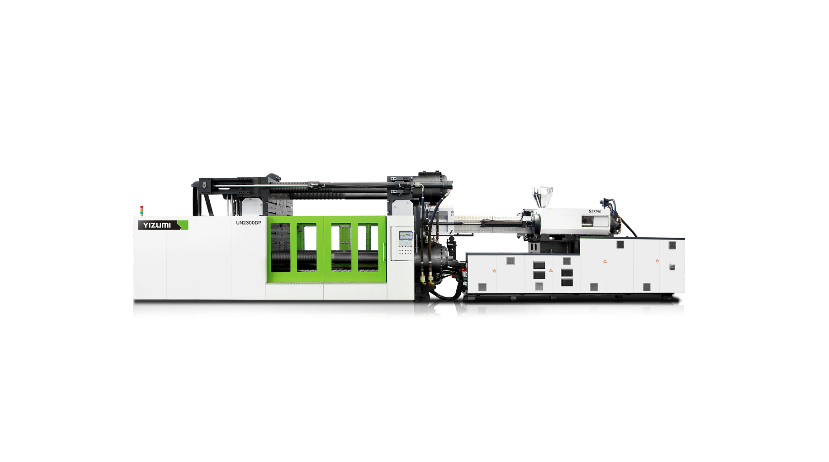

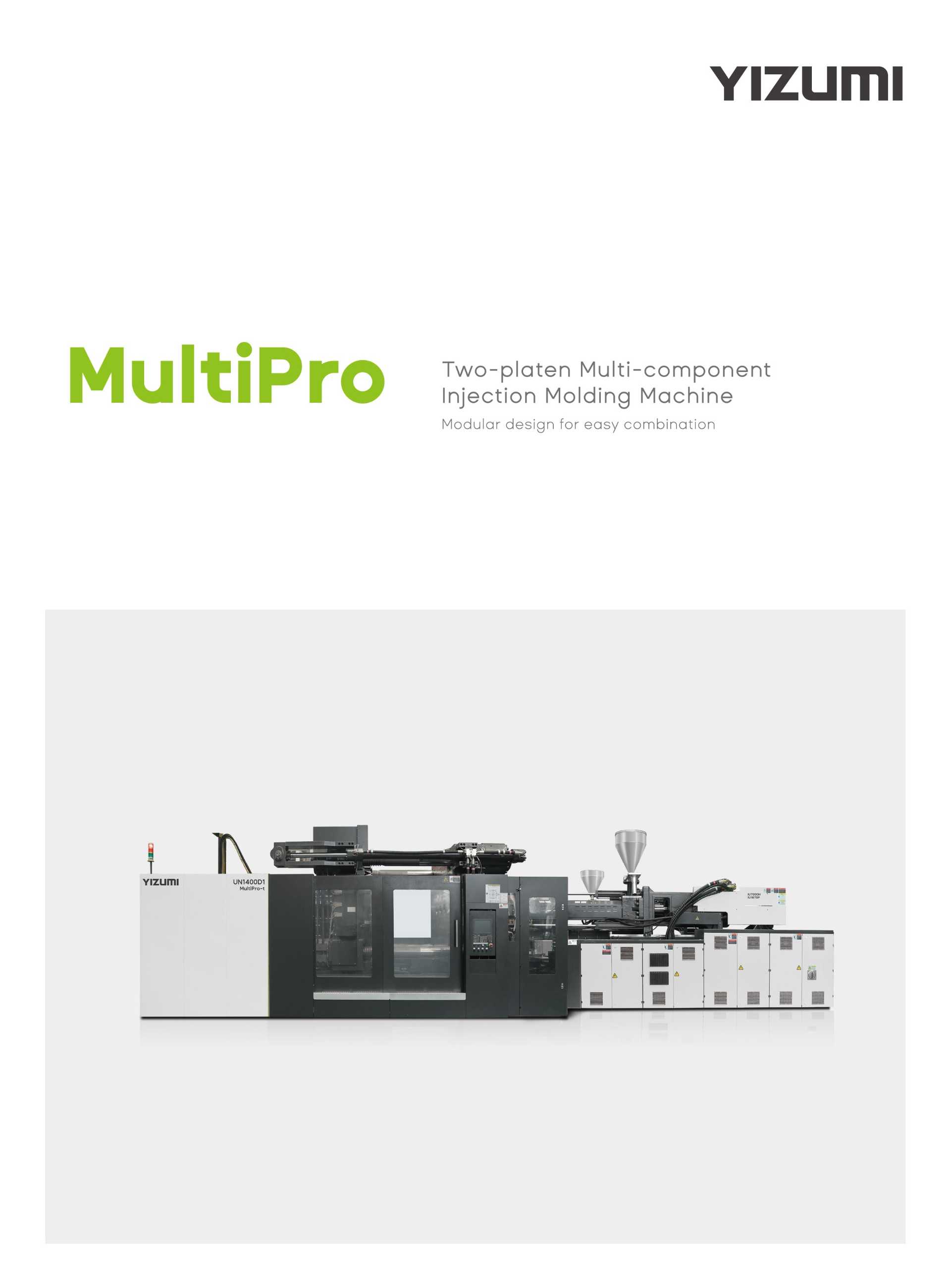

Machine Introduction Video

Machine Introduction Video

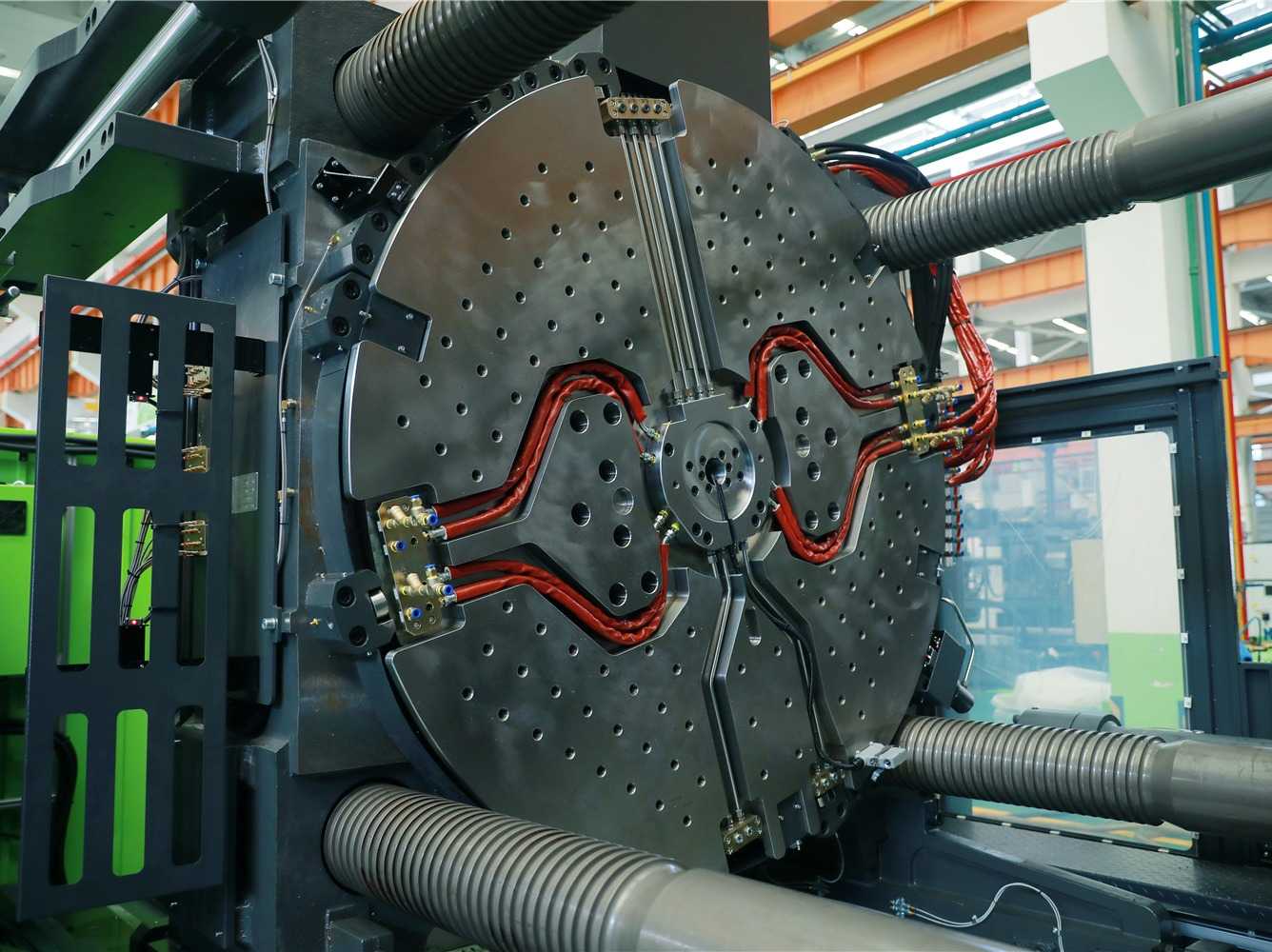

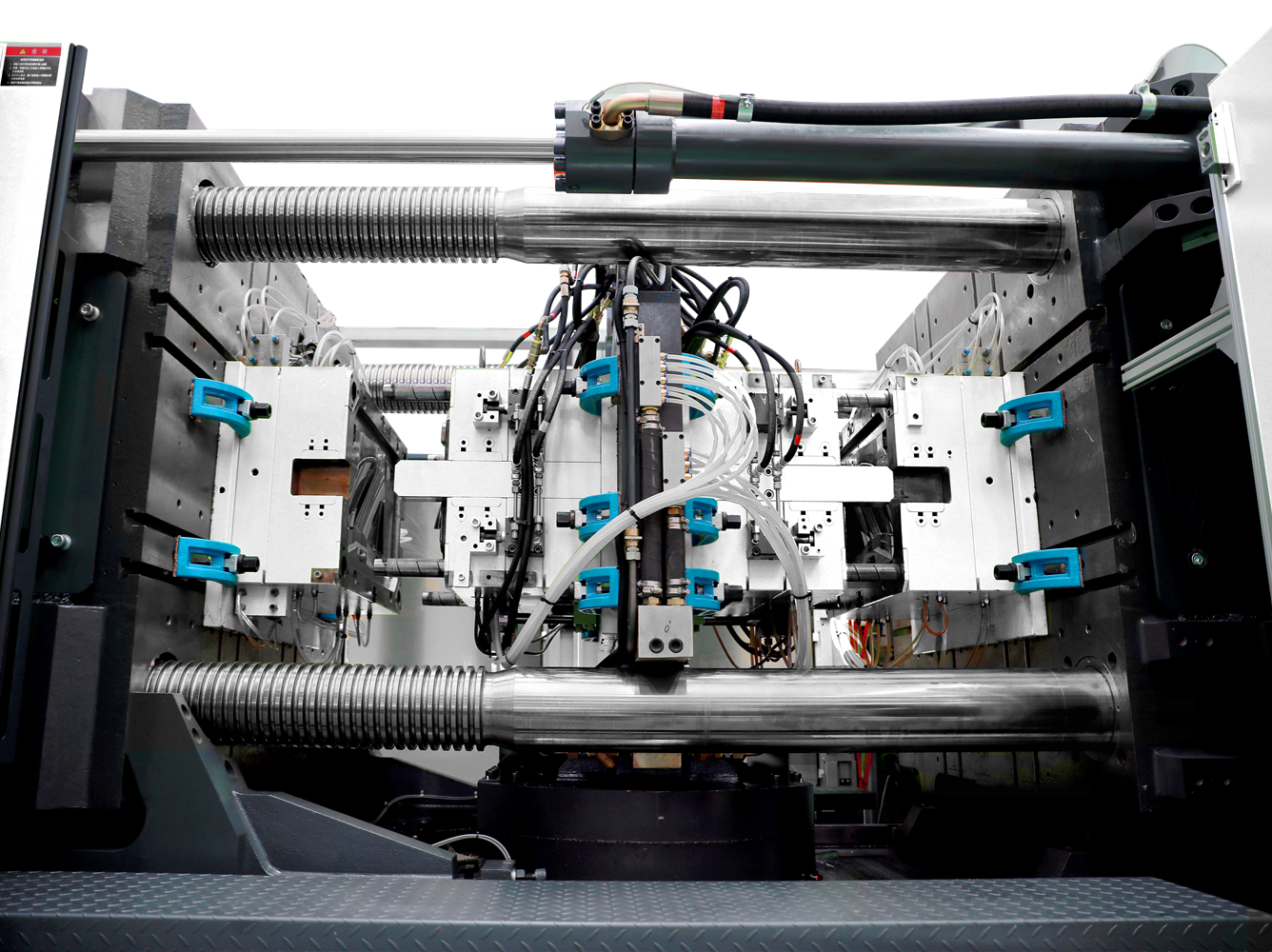

Clamping Unit

Integrated turntable

- Integrated design, high rigidity, large bearing

capacity and compact structure;

- The turntable is standard with servo motor with high precision and rotation speed. It can be equipped with multiple groups of water-oil-gas diversion systems at high flow rate.

- The turntable is standard with servo motor with high precision and rotation speed. It can be equipped with multiple groups of water-oil-gas diversion systems at high flow rate.

Digital closed-loop positioning control technology

(DCPC)

Turntable driven by servo motor is controlled by DCPC

technology, with high rotating speed, smooth operation

without impact, accurate positioning and repeatability

up to ±0.005°.

Automatic flow-distribution shaft system

Turntable is applied with German automatic flow

distribution shaft system, with double layer structure

for oil-water separation. It offers centralized

management for oil, water and gas. Multi-angle rotary

of station is also available by 0° , 90° ,120° , 180°

,240° or 360° , no wear and no tangling for pipeline,

wider application.

Injection Unit

High injection repeatability

Based on European single-cylinder injection molding

technology, it brings low injection inertia and high

leak-proof performance of cylinder;

Also combined with high mixing anti-stick screw and precise temperature control, injection stability is further enhanced, making the repeatability of product weight up to 3‰.

Also combined with high mixing anti-stick screw and precise temperature control, injection stability is further enhanced, making the repeatability of product weight up to 3‰.

Proportional valve-controlled back pressure

Precise control to enhance injection stability and

provide necessary conditions for excellent

plasticizing effect.

New-generation PID temperature control

With adaptive PID temperature control, the static

temperature control accuracy reaches up to ±0.5℃

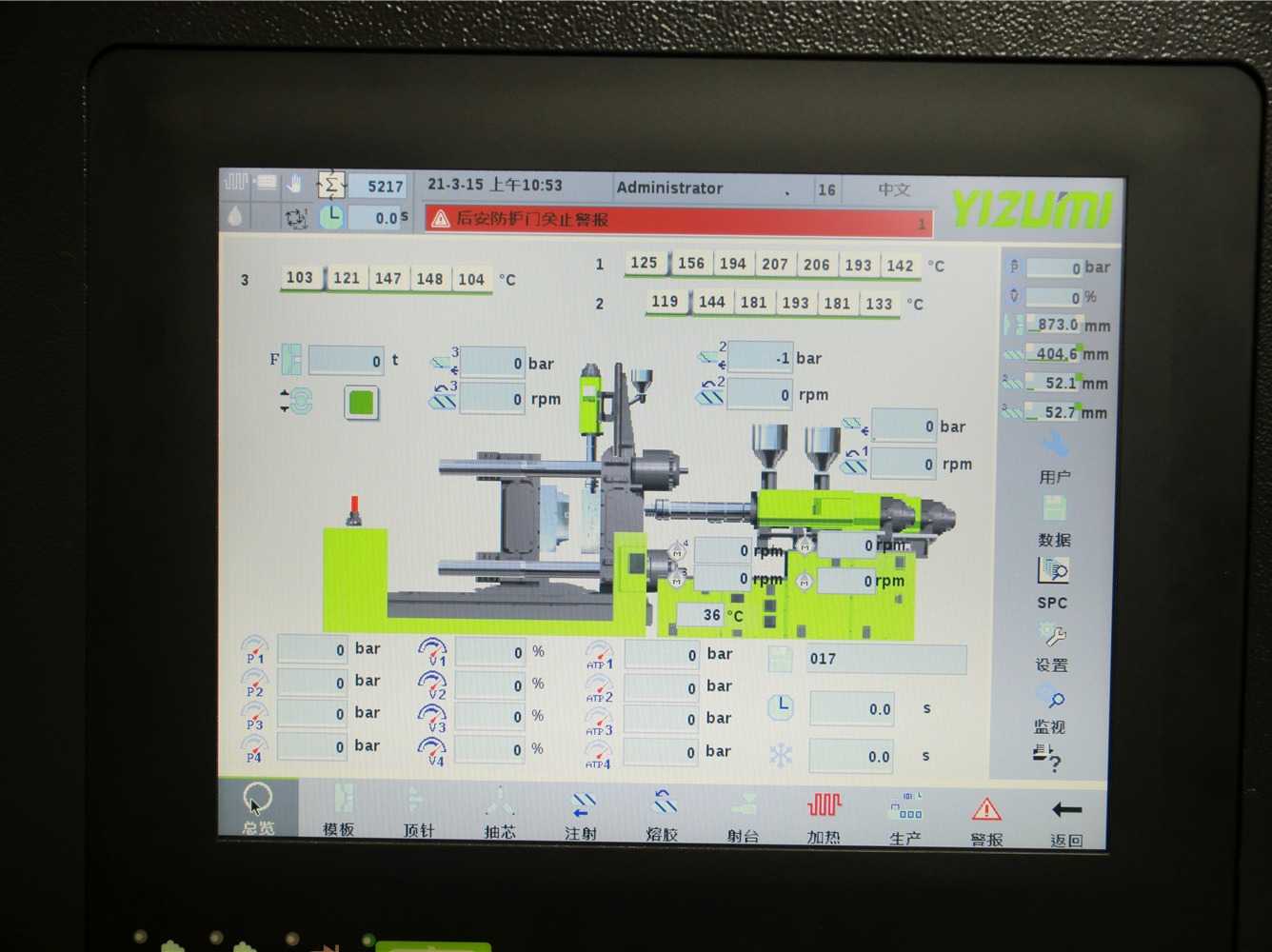

Precise control, reliable and stable, user-friendly design

Austrian KEBA controller is standard for two-platen

multi-component injection molding machine. Controller

design is reliable, stable, safe and user-friendly,

applicable to various multi-component molding solutions,

improving customer experience.

Horizontal turntable two-way injection molding

Horizontal turntable is suitable for the molding of long

or large two-color products. It can help machine largely

reduce clamping force comparing with vertical turntable.

Also horizontal turntable can cooperate with the third and

the fourth injection units(W type, L type, V type, etc.)

in multi-component molding, providing more cost-effective

solution.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data,

collected and processed by YIZUMI in relation to my

inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected

and processed by YIZUMI in relation to my inquiry.