Machine Introduction Video

Machine Introduction Video

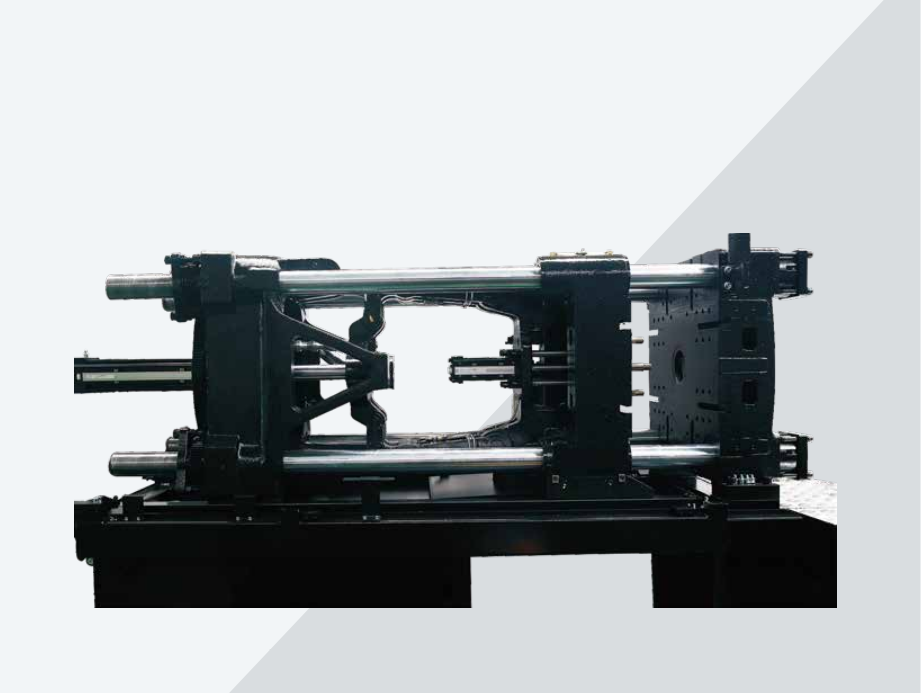

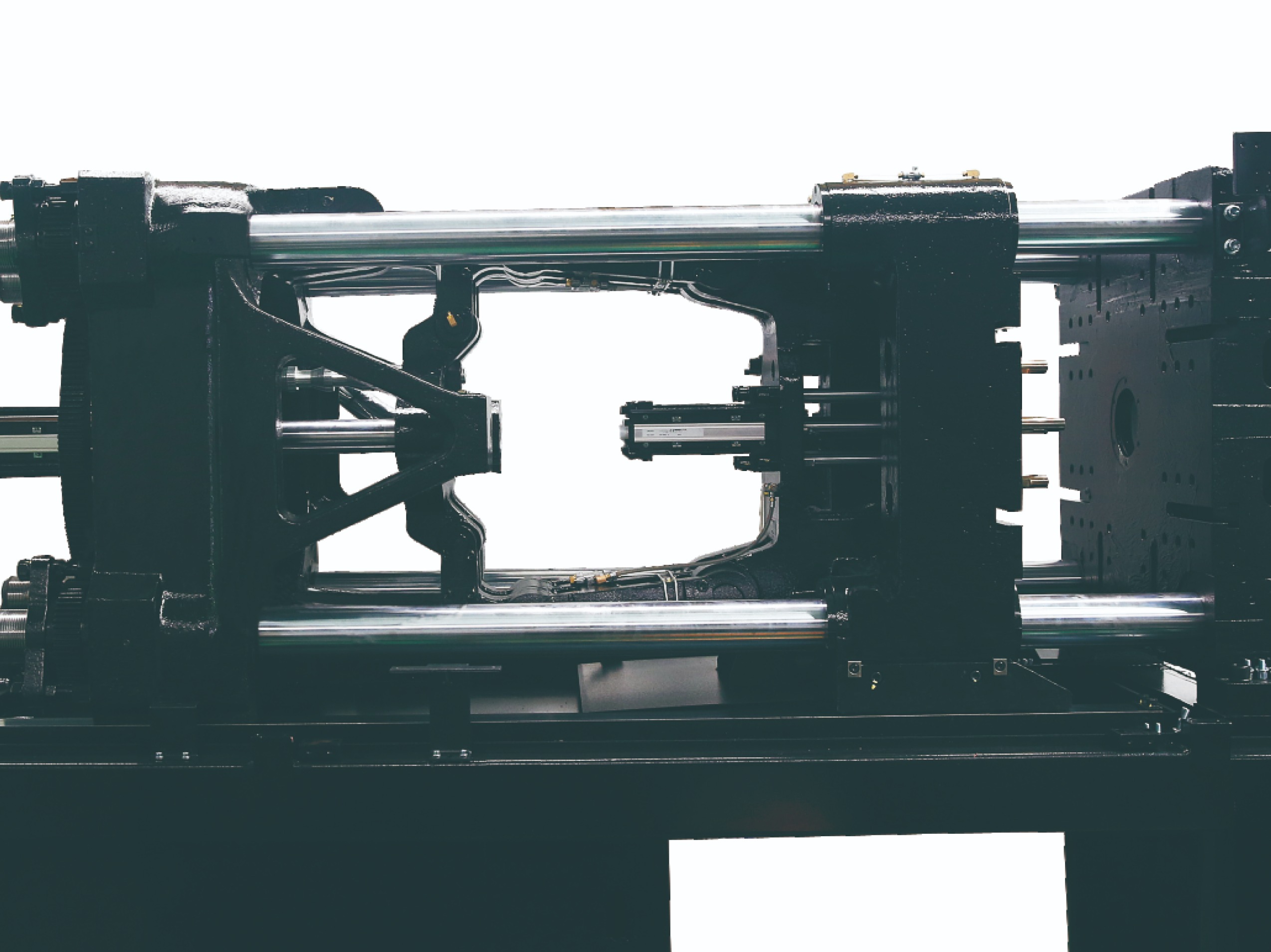

Clamping Unit

High-rigidity T-slot platen

Increases the overall rigidity of clamping unit by

30%, brings convenience for installation and removal

of mold, reduces the wear of thread due to long-term

use of screw hole and extends the life of platen.

Closed-loop control of mold open position

The mold open position accuracy is smaller than 2mm

and repeatability is below 0.3mm.

Anti-tilt platen support design

Increases the smoothness of motion, lowers friction,

improves the efficiency of motion, reduces energy

consumption and prevents the platen from tilting so as

to protect the mold.

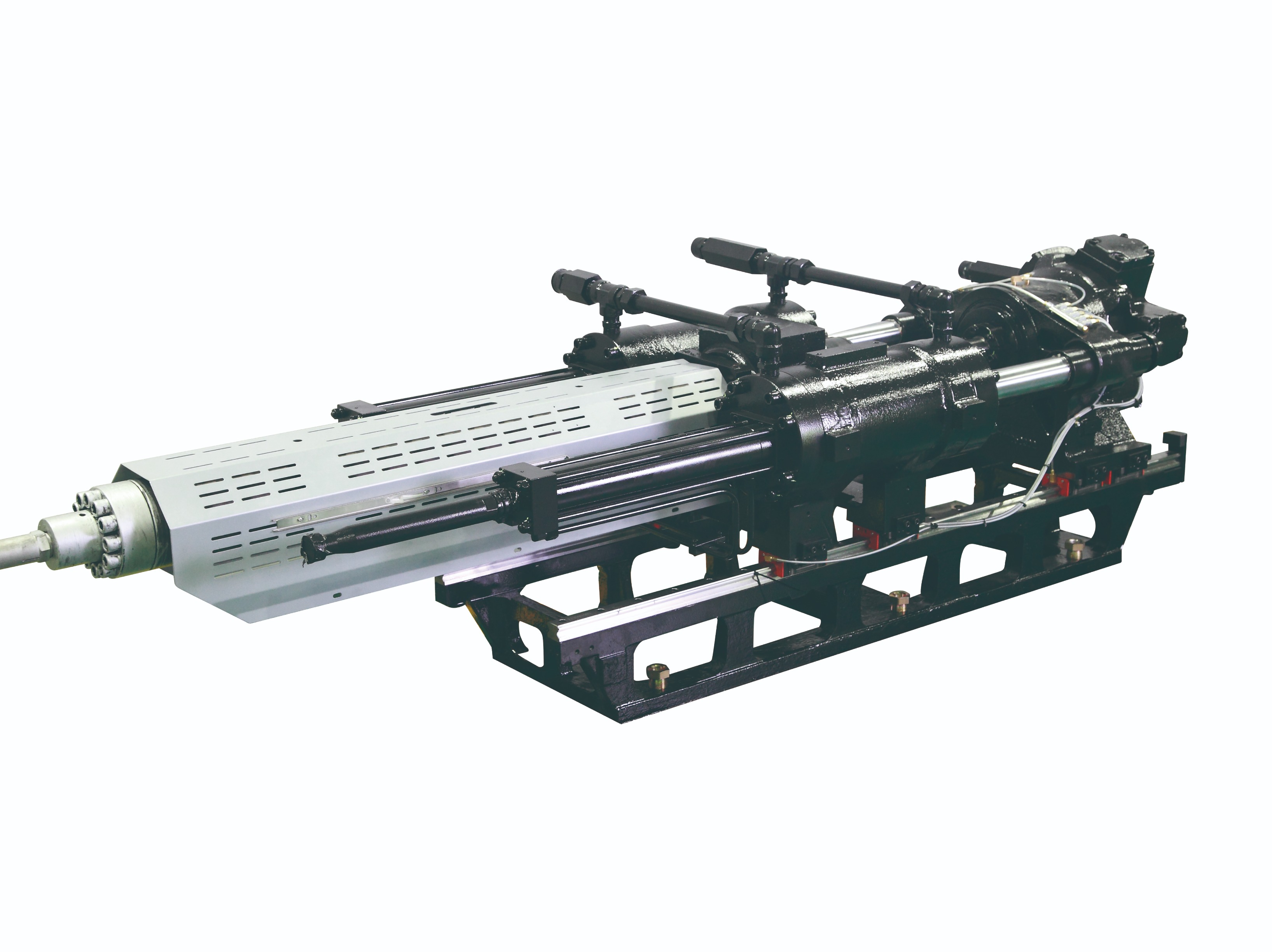

Injection Unit

Integrated linear guide rail structure

One-piece supporting base integrates with linear guide

rails, which minimizes the friction to motion,

increases injection accuracy and enhances plasticizing

efficiency.

Horizontal dual-carriage design

Effectively eliminating rotary torque to ensure a

reliable and stable injection.

New universal screw and barrel unit

Further optimizes color mixing and plasticizing

efficiency, easy color change and cleaning, low shear

without temperature rise and wider applicability.

Yizumi’s third-generation energy-saving servo technology

To achieve superior performance in stability, reliability,

durability, energy conservation, efficiency and low noise,

the servo system uses 30%-80% less energy than

conventional hydraulic machines.

The accuracy of closed-loop hydraulic oil temperature control, which is the new function, is ±0.5℃ with further increased stability.

The accuracy of closed-loop hydraulic oil temperature control, which is the new function, is ±0.5℃ with further increased stability.

Mirle MK500 control system

- The control unit adopts Cortex-A55 processor with scan

time of 0.25ms, speedy response and accurate control.

- 1000 sets of mold data memory, USB port for extension of storage.

- 7+1 sections of PID temperature control supports switchover between type J and type K thermocouples.

- Automatic PID tuning improves the temperature control accuracy.

- Integration of common software (like IMC, robot, needle valve) meets different injection molding process requirements.

- 1000 sets of mold data memory, USB port for extension of storage.

- 7+1 sections of PID temperature control supports switchover between type J and type K thermocouples.

- Automatic PID tuning improves the temperature control accuracy.

- Integration of common software (like IMC, robot, needle valve) meets different injection molding process requirements.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data,

collected and processed by YIZUMI in relation to my

inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected

and processed by YIZUMI in relation to my inquiry.